|

|

|

|

| STEP 3 of 10 - Preventive Maintenance

Schedules |

|

|

Previous |

Next

Previous |

Next  |

|

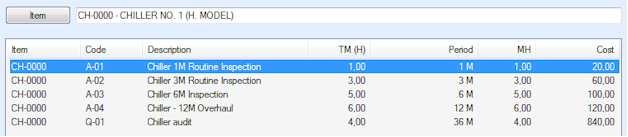

The maintenance plan of the equipments

should be made in accordance with the manufacturer

recommendations (manual of the equipment), the actual operating

conditions and the experience.

An item’s maintenance plan is a combination of maintenance

schedules (that include work schedules). These maintenance

schedules are, in practice, the contents of your daily Work

Orders.

|

Preparing a maintenance schedule (MSch) |

|

Right-click an item

and choose the option <Maintenance Plans>. This will

show a list of the item’s maintenance schedules. |

|

Select <New> to

show the <New Maintenance Schedule> form. |

|

By choosing the Work type, the system automatically

suggests a code. You should use this code. |

|

Specify planned

maintenance time (TM). |

|

Set maintenance

schedule Periodicity (calendar time, running records or

a combination of both) |

|

By specifying a

<Next MSch> (Next Maintenance Schedule), you will create

a maintenance cycle. Preventive Work Orders (WOs) for

this item will then be generated according to the

maintenance cycle you have created. In practice, with

only one WO you will be able to run through all of the

item’s maintenance schedules, according to the

maintenance cycle you defined. |

|

In the <Tasks>

tab, describe the tasks to be carried out |

|

Optionally,

specify planned resources (Man-Hour, Stock items and/or

third party services) to carry out these tasks. When

creating this WO, these planned resources will then be

transferred to the WO, where you will be able to analyze

deviations. |

Tips & best practices

Tips & best practices |

|

Maintenance plans must be prepared

according to manufacturer

recommendations; do not be over

ambitious in the frequency of the

systematic work schedules as this may

overload your human resources and harm

the accomplishment of the plan. |

|

When preparing a work schedule, before

describing the tasks to be carried out,

you should include reference to the

equipment’s maintenance manual (or other

relevant documentation) and essential

safety precautions |

|

You should only record in the system

work schedules that are relevant and

that need to have proven maintenance

history. You should not waste time

managing daily or weekly work orders. In

these cases, a simple check list

worksheet is more effective. |

|

|

|

|

| |

|

|

| |

|

|

Products |

|

|

| |

Contact us

Contact us |

|

|

| |

| |

| |

|