|

|

|

|

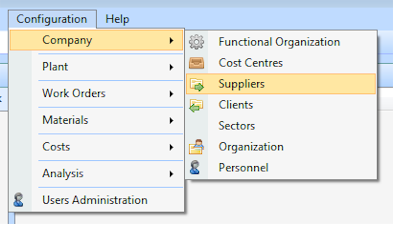

| STEP 1 of 10 - Configuration |

|

|

Previous |

Next

Previous |

Next  |

|

System configuration is the first step in any maintenance management software.

This first step is very important, as you will set basic

rules that will follow the organisation for many years, so you should make wise

decisions.

InnWinWin is already pre-configured for a typical building and ready to use,

although some adjustments to your specific case are required.

In this wizard, we will focus on the system’s main configurations.

|

ECompany - Functional organisation |

| |

Functional organisation is like an X-ray of your

plant where you see all the systems inside it and the

equipments that contribute to the performance of each

function – forklifts, cranes & suspensions, electrical

workshop, etc... Coordinating your equipments into

systems enables you to analyze them individually and

diagnose problems that may affect the overall

performance of a specific system. Functional

organisation gives you a detailed description of your

plant in an engineering point of view. |

|

|

|

Company - Cost Centers |

| |

Maintenance information is expressed in a financial

point of view through Cost Centers. A concise and

convenient way for Financial Departments to analyze

maintenance. You may typically consider each plant a

cost center, within which you will have sub-cost

centers. |

| |

|

|

Company - Suppliers |

| |

Suppliers that are relevant for maintenance:

maintenance service providers, equipment manufacturers

or resellers and parts and materials suppliers. |

| |

|

|

Company - Clients |

| |

Setting up and recording clients only makes sense for

maintenance service providers that wish to manage their clients plant

maintenance with ManWinWin 5. |

| |

|

|

Company - Technical Intervention Area |

| |

Organizes the internal structure of the people actually carrying out maintenance

operations in the form of an organisational chart, where the several functions

are specified in a hierarchy and where the people performing the maintenance can

be coordinated.A maintenance department, even with more than one workshop, is typically

organized into intervention areas like Electrician, Polyvalent, Plumber,

Foreman, among others. A standard man-hour cost is established for

each intervention area and this cost must reflect

average cost with assigning a specific technician to

maintenance work. |

| |

|

|

Company - Personnel |

| |

All people – internal or external personnel – with

possible intervention in maintenance tasks must be

recorded into the software and assigned a specific

technical intervention area (as seen above). |

| |

|

|

Plant - Item types |

| |

Setting up your plant’s Item Types means creating a consistent coding system for

your maintenance items. With a simple and suggestive two-letter system, you may

establish, for example, PU = PUMP, PP = Piping, etc…

Each Item Type has a technical datasheet which you can

customize. You have up to 40 particulars with which you

can characterize the item and then use for search

filters or cross analysis. |

| |

|

|

Plant - items families |

|

Item family may be an interesting feature for you.

In practice, this feature allows you to group

maintenance items according to its basic function,

enabling you to analyze these particular groups

individually |

| |

|

|

Work Orders - Causes & Symptoms |

| |

A set of key descriptions used to characterize

breakdowns. This feature enables all users in the

organisation to use a uniform language when addressing

breakdowns and allows important cause and symptom

analysis. |

| |

|

|

Work Types |

| |

When managing maintenance, it is useful to set different Work Types. This

classification allows the manager to sort out Effort and Costs of each

maintenance type, giving him very good insights on which maintenance types are

Effort and Costs mostly concentrated, providing valuable information for results

optimization. Maintenance Work can be classified into 3 major types that can still be divided

into “sub-types”:

- Systematic Maintenance

(Preventive Systematic, inspections, lubrications)

- Condition based (preventive based on

equipment condition)

- Corrective Maintenance (Repairs) |

| |

|

|

Materials – Stock item coding standard

|

| |

Stock item coding standard – this means establishing a structured organisation

of Classes, Families and Sub-Families. The idea is to create a logical structure

Class / Family / Sub-Family through

which the manager will organize and have, inside each structure, only a

reasonable amount of different stock items, easily searchable.

Example: Class C – Consumables, Family AV –

HVAC, Sub-Family FI – Filters, 023 – Sequential number. |

| |

|

|

Costs – Accounts |

| |

Account means organising a cost by its nature or its

type. The manager should set relevant Accounts that fall

into his area of responsibility. |

| |

|

|

Costs – Document Types |

| |

Document types are a mandatory configuration to

create cost documents and cost items. Invoice, Receipts,

delivery notes are typical cost documents. |

| |

|

Tips & best practices

Tips & best practices |

|

Configuration of the system must be seen

as the foundations of a building. This

stage requires some time and thought. |

|

Tree structures (Ex: Cost centers, staff

organisation, etc…) should not have too

many levels. Keep it simple and friendly

for all users in your organisation. |

|

Before defining any coding system,

always bear in mind an upper limit and,

according to that upper limit, start

your codes with zeros on the left.

Example: if you have up to 1000

suppliers, start with Supplier nr. 0001,

nr. 0002, … , nr. 0345, and so on. |

|

|

|

|

| |

| |

|

|

| |

|

|

Products |

|

|

| |

Contact us

Contact us |

|

|

| |

| |

| |

|