|

|

|

|

| STEP 2 of 10 - Register your equipments |

|

|

Previous |

Next

Previous |

Next  |

|

After

setting basic configurations, maintenance management system

implementation starts with introducing necessary information to

get management underway. This means recording your maintenance

items and components, preparing preventive maintenance plans and

scheduling your first set of Work Orders (WOs). After

setting basic configurations, maintenance management system

implementation starts with introducing necessary information to

get management underway. This means recording your maintenance

items and components, preparing preventive maintenance plans and

scheduling your first set of Work Orders (WOs).

In this stage, you will have to decide which items you are

actually going to manage and which items you are simply just

going to record in the system.

A maintenance item does not necessarily have a specific

preventive maintenance plan. There are items that don’t require

preventive maintenance and there are those which you choose not

to plan any preventive maintenance tasks (for example, piping,

electrical cabling, doors and the like). It is very important,

however, to have a complete inventory of your facility, even

those items with no preventive maintenance, as this will enable

you to keep track of these items at all times or even register

possible corrective actions on them.

Any maintenance item needs 3 things: coding; to be functionally

coordinated; and allocated to a cost center. It also includes

planning preventive maintenance and scheduling WOs, if you

decide to manage the item’s preventive maintenance.

|

Coding and recording equipments |

|

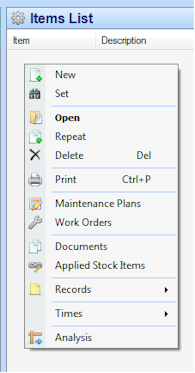

In the items list,

select <New>. The <New Item> datasheet will appear |

|

Set the item’s

structured code by selecting the item type and the

sequential number (press <…> for options). Example:

AC-0023 for an Air Conditioner. |

|

When identifying an equipment, be sure to give it a

unique and personalized description. Example: Air

Conditioner Split Directors Room |

|

Indicate

Functional organisation and Cost Center coordinates

(configured in Step 1) |

|

Introduce the

item’s technical particulars and relevant operational

data |

|

Complete this

record by clicking OK button on the bottom-right corner

of the item datasheet |

Tips & best practices

Tips & best practices |

|

Fields marked in Red are mandatory;

fields marked in blue are recommended;

all the other fields are optional |

|

Recording all your equipments in the

system should not be carried out too

fast. If you really want to be

productive at this stage, we recommend

you register one item of each type with

complete and relevant information and

maintenance plans and only then use

Repeat to register the other items of

the same type. |

|

Repeat is a very good resource to

improve productivity when constituting

the maintenance information, but needs

to be handled with care: you should only

repeat a record if it is made up of

complete and reliable information and if

it suits well your case. Otherwise,

repeating a poorly made record may

decrease rather than improve

productivity |

|

|

|

|

| |

|

|

| |

|

|

Products |

|

|

| |

Contact us

Contact us |

|

|

| |

| |

| |

|